On Monday 31

th of August 2009 it was the day of starting the RF Processing procedure.

RF Processing is a neccesary step during the installation of the RF accelerator in which gradually increased RF power is applied to the cavity in order to clean and smoothen the inner surface. As a result the cavity can hold increasingly higher electric field levels without resulting in a breakdown event.

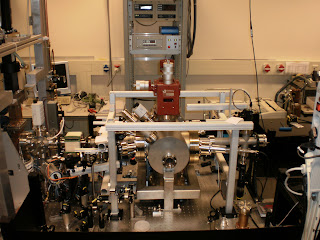

In order to perform a successful RF processing procedure, we have equiped the setup with several detection systems:

1-

Breakdown detector: A piece of analog electronics monitors the backward reflected RF waves from the cavity and senses very abrupt changes in RF power that will occur upon breakdown inside the cavity. This is due to the change of impedance of the cavity when a breakdown occurs. When a breakdown is detected the RF pulse is immediantely interrupted.

2-

Vacuum pressure monitor with switch: When the vacuum pressure inside the cavity exceeds a certain level the RF power to the cavity will be interupted untill the pressure has droped below the level again.

3-

Faraday cup or electron beam dump at the exit of the cavity to monitor the electrons coming out of the cavity. The signal is presented on an oscilloscope.

4-

Photodiode that monitors the light output of the cavity to detect the intensity of the breakdown event. The signal is presented on an oscilloscope.

5-

Photodiode that monitors the light output near the RF window to detect the intensity of the breakdown event.

We have a few parameters that we can set in the system:

1- RF peak power by changing the RF input power to the Klystron tube by changing a variable discrete attenuator between 0.0 and 15.5 dB in steps of 0.5 dB.

2- RF peak power by changing the high voltage setting of the modulator. This can be seen as a fine adjustment of the RF power as compared to option 1.

3- RF pulse length by changing the modulator pulse length. This can be changed between 0.50 and 2.80 us flat top.

4- RF pulse repetition frequency can be set between 0 - 100 Hz as long as the average power of the modulator does not exceeds 6.5 kW. In general, we do not exceed 50 Hz.

The method that we apply is to start with the setting of the shortest pulse and increase in RF power. After a certain level has been achieved, the pulse length is increased, while keeping the maximum field strength in the cavity constant. Do to this the RF filling time of the cavity has to be taken into account. Once dark current is observed from the cavity, this is easily achieved by keeping the dark current constant. The last step is to increase the pulse repetition frequency. This procedure can be repeated untill the maximum RF input power is reached.

At 18:00 that day we started under supervison of the radiation safety department of TU Delft the RF processing procedure. We replaced the 20 dB attentuator at the input of the preamplifier to a 10 dB. Soon after the start we reached the level of 1 MeV electron energy. By midnight we haved reached 2.9 MW input power and 2.5 MeV electron energy. The estimated electric field inside the cavity is about 60 MV/m.

The accelerator is control from the control room. Left to right: Juleon Schins, Laurens Siebbeles, Koos van Kammen and Walter Knulst. |

Walter Knulst is controling RF processing from the accelerator GUI build in LabView. |

Walter Knulst together with Martien Vermeulen who is the allround electron accelerator engineer. |

Another look at the control room. |

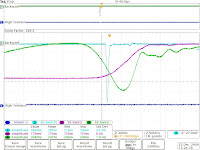

A breakdown event is recorded by the oscilloscoop. In green you can see the abrupt change in RF reflection from the cavity and 400 ns later the breakdown detector has switched of the RF power. |

Another breakdown event, which has unfortunately not been detected by the breakdown detector due to the fact that the rising edge is less steap than the event to the left. |